Introducing HECTOR Mini - A 3-D printed cost-friendly bipedal humanoid robot

Published:

Some background and motivations for this work

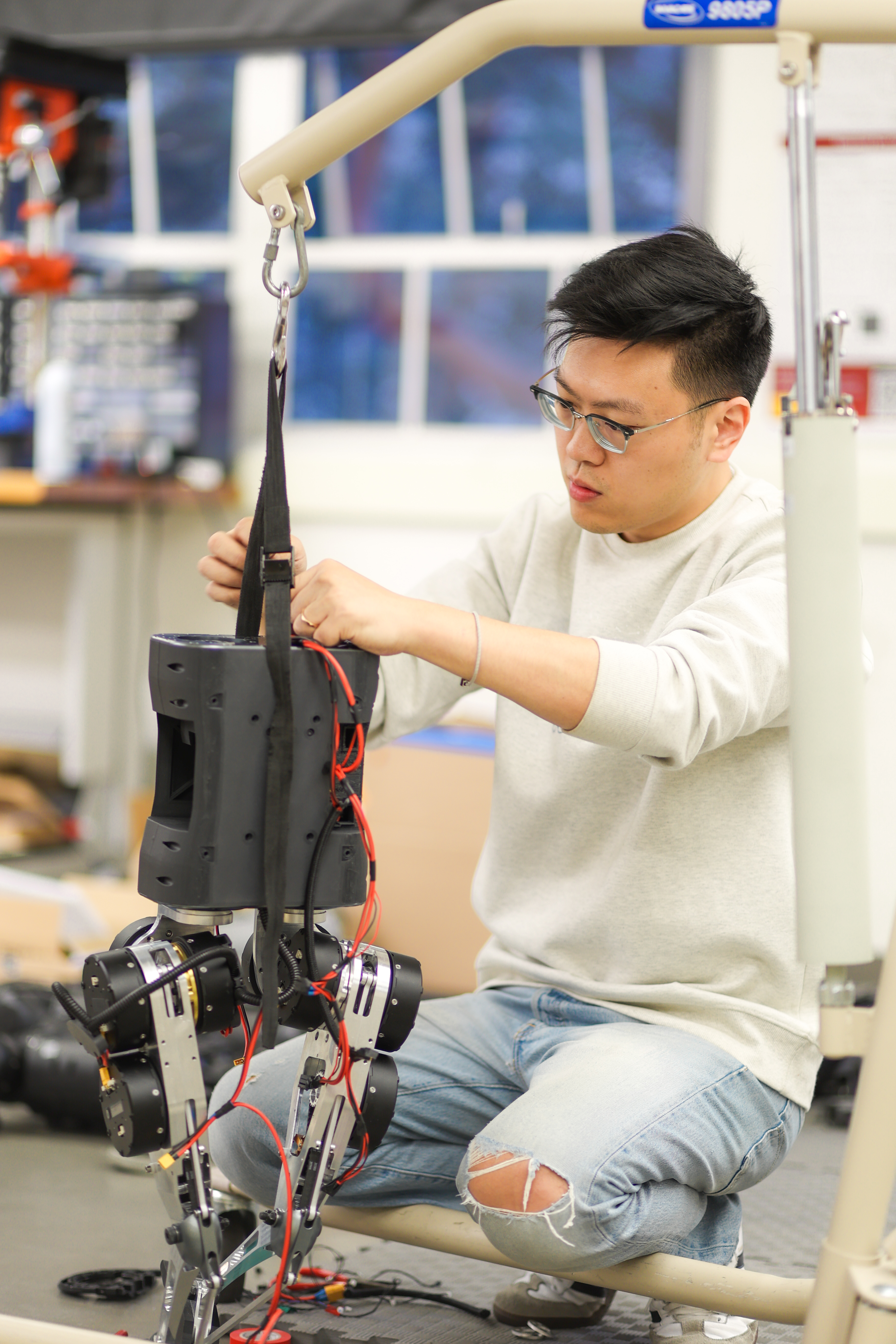

It is always a pleasure to work on some hardware aspect of robotics. Throughout my PhD, I had the chance to learn (from my labmates) and work on many aspects of the hardware and systems of legged/humanoid robots. We have learned a lot from creating and building the HECTOR v1 and v2 platforms. Towards the end of my PhD, I wanted to give my last shot at designing and creating a new humanoid robot, with something new, and hopefully give some new(old?) perspectives on humanoid robotics to the community.

When I first started my PhD, there weren’t many available bipedal robot hardware options on the market, so we decided to make our own biped out of the Unitree A1 quadruped. Back then, inspired by many successful optimization-based control works such as the MIT Cheetah series, the design of the robots was mostly focusing on reducing the leg inertia for more dynamic motion potentials. Fastforwarding to today, the humanoid robot design language has changed quite a bit – from low-inertia legs with careful design of transmissions, to motor-at-joint direct drives. This was largely influenced by the rise of RL and the need for more robust hardware and a smaller sim-to-real gap on the hardware side. It is an inevitable evolution; however, a bit sad to see some of the clever mechanisms have gone.

The idea

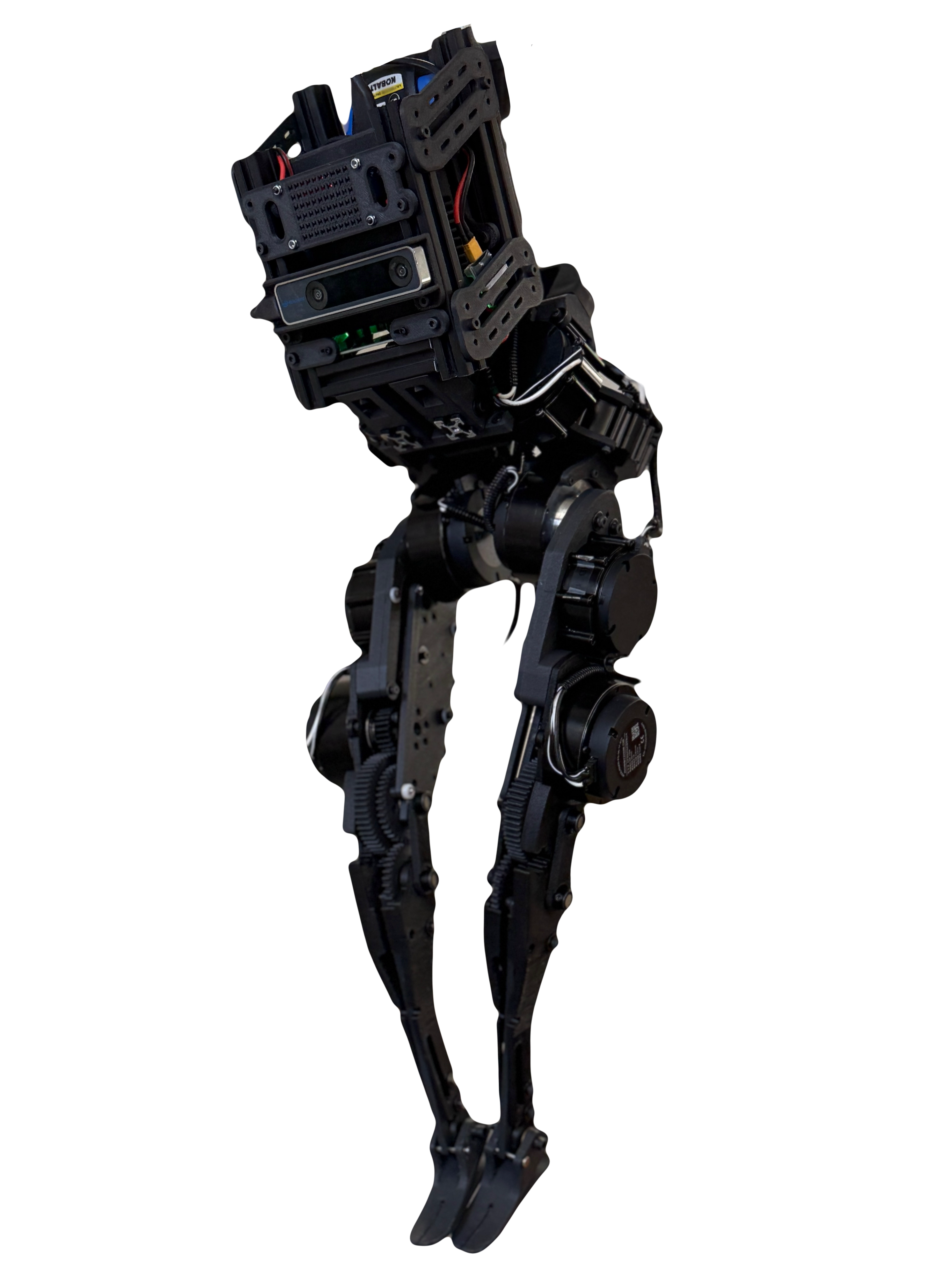

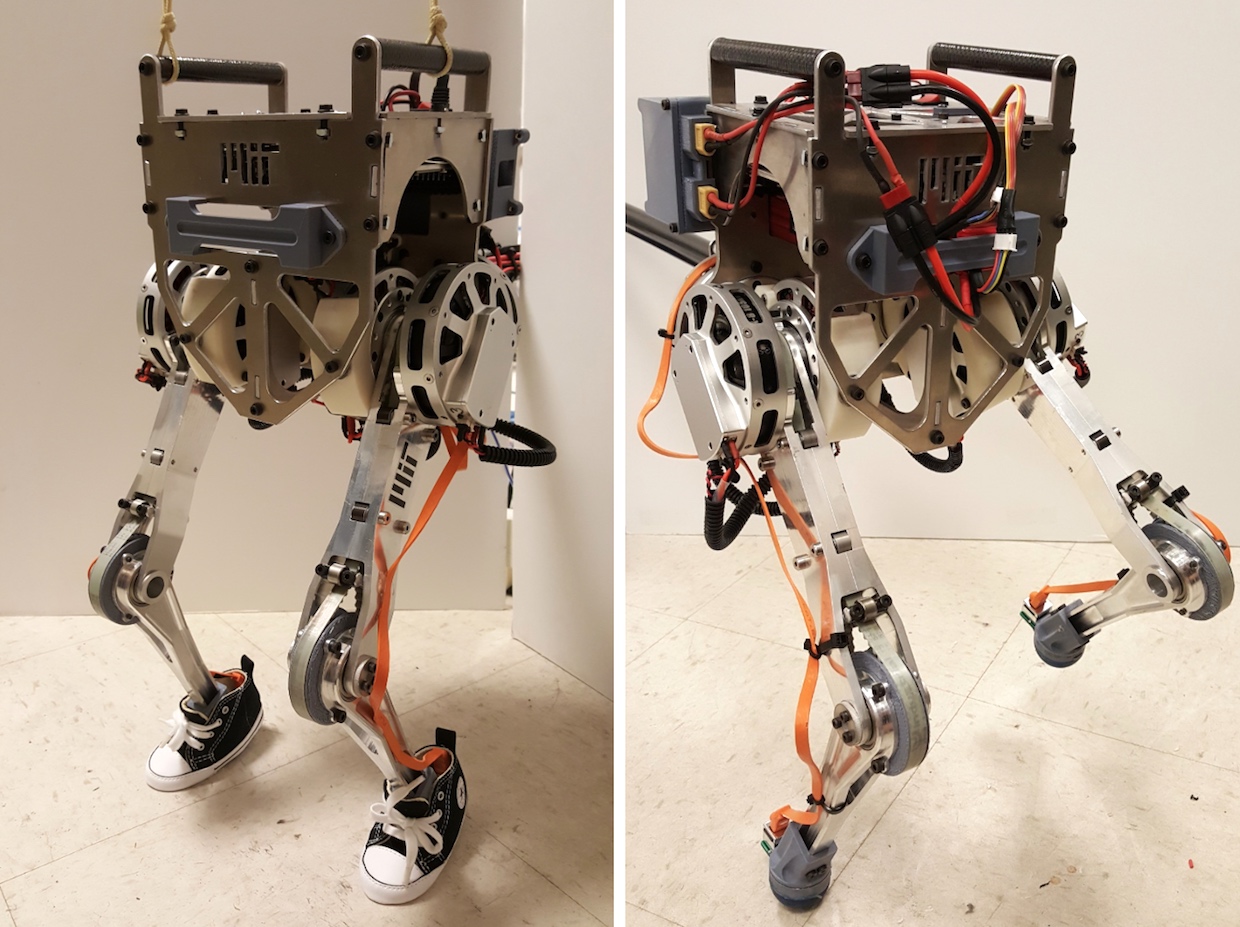

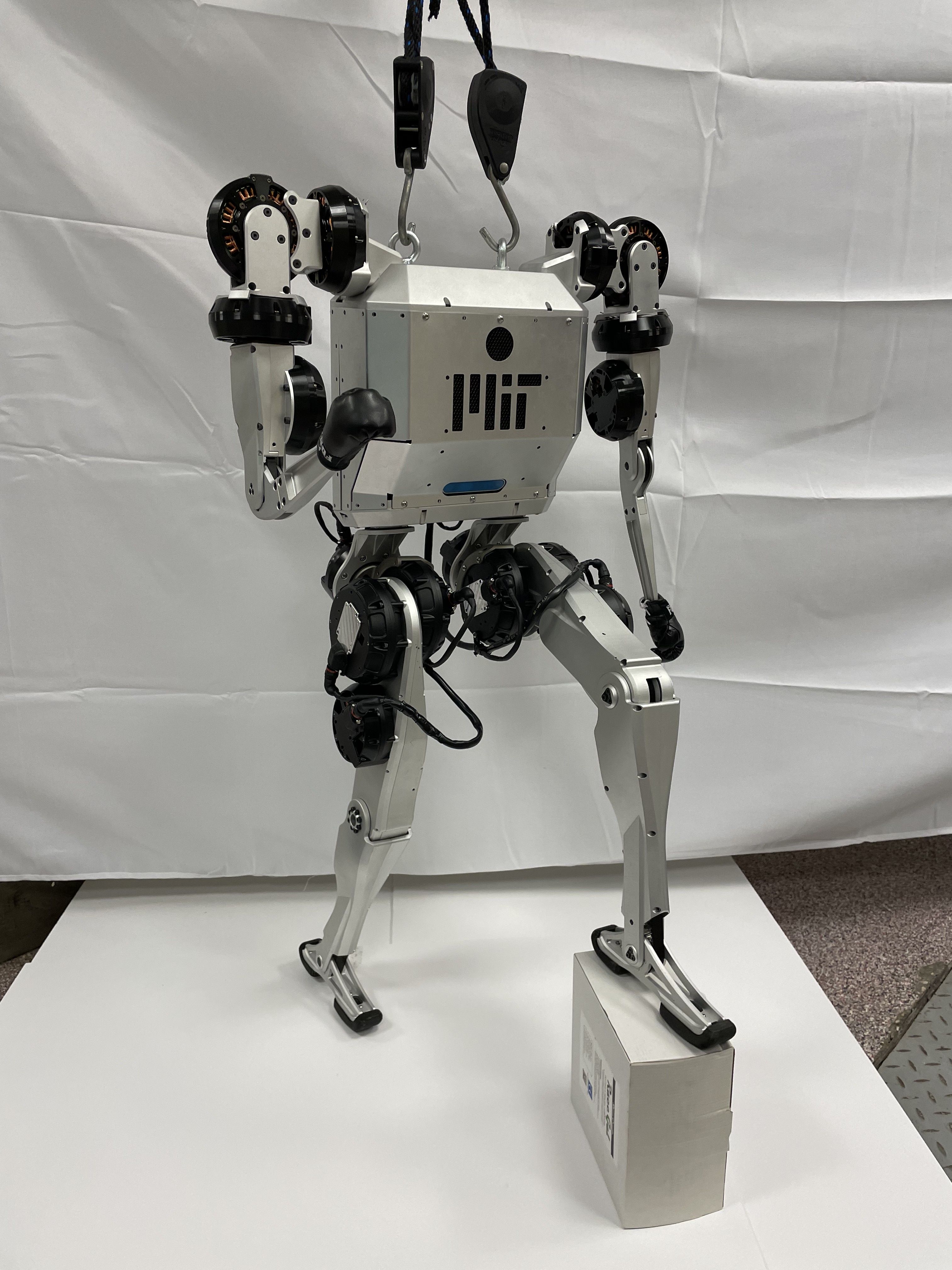

First, let’s talk about the low-inertia leg designs. We have seen a bloom of these from the mid-2010s to 2020-ish, led by the ATRIAS -> Cassie -> Digit series with beautiful ostrich-like legs driven by parallel linkage mechanisms. Later we see MIT’s little Hermes and humanoid robot sharing similar belt-pulley driven mechanisms, eliminating some range of motion constraints by the rigid linkages. HECTOR V2 uses a similar belt-pulley mechanism for the knee joint and linkages for the ankle actuation, a mix of both worlds. The immediate challenge we faced while using timing belts was tensioning, which required the structure to be very solid to work well. We have bent so many upper leg aluminum plates while playing around with this mechanism in the first prototype (and hundreds of dollars worth of belts too…). With that, in the HECTOR Mini project, I want to explore something different, something maybe simple and well-tested in other mechanical systems. Gear trains have come to my mind as the first choice. However, there are still many challenges with gears, which I will cover later.

Figure 2: ATRIAS, Cassie, and Digit Robots ( image source ). |  Figure 2: Little Hermes Robot. ( image source ). |  Figure 2: MIT Humanoid Robot ( image source ). |

Then, let’s think about the current joint designs of humanoids (TBC)